Polyurethane Raw Materials and Systems

It covers the polyol and isocyanate raw materials used in the production of the following polyurethane sponges and foams and chemicals according to product groups, our primary duty is to provide our customers with product supply from reliable sources.

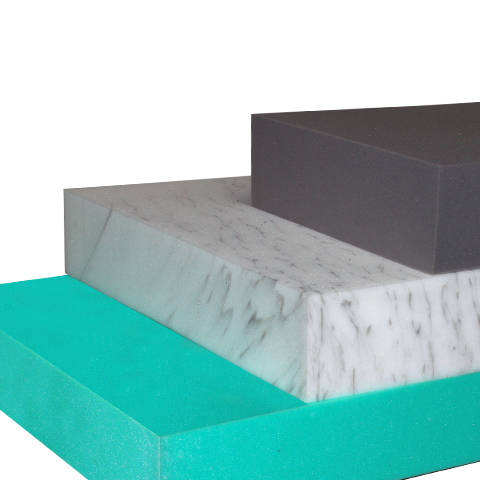

Low density (15-40 kg/m3) sponges are produced with block sponge production technology. In continuous lines, production can be made in blocks upto 2,4 meters in width and 30 meters in length upon request.

Polyether POLYOL and TDI (80/20) are mainly used in the production of foam blocks. It is also possible to use MDI. There is no pre-prepared system in continuous sponge production. According to the density and properties of the foam to be produced, the Formulas are prepared daily and loaded into the machine.

Mold is more risky than sponge production. Since the temperature inside the block reaches 160 degrees, good ventilation should be done and user must be careful in the production line and in the resting areas.

Especially in low density foam productions, FOAM GRADE methylene-chloride should be used to cool the system and prevent yellowing in the middle area. Even if the technical methylene does the same task, it does not give the same quality and result.

PROPULSOL is a product that produced for this purpose. By using polymeric polyol with high solid content, the resistance and quality of the sponge can be increased. In order to produce flame lamination sponge, it is necessary to use a non-flammability additive. It is possible to offer a widerange of products in terms of density, color and physical properties. Block sponge production is very open to technical problems. If the formulation selection, additives such as amine, tin and silicon are selected correctly, these problems might be minimized.

Sponge additives are shipped in pail or in barrels, while POLIOL and TDI (MDI) are mainly shipped in tank containers.